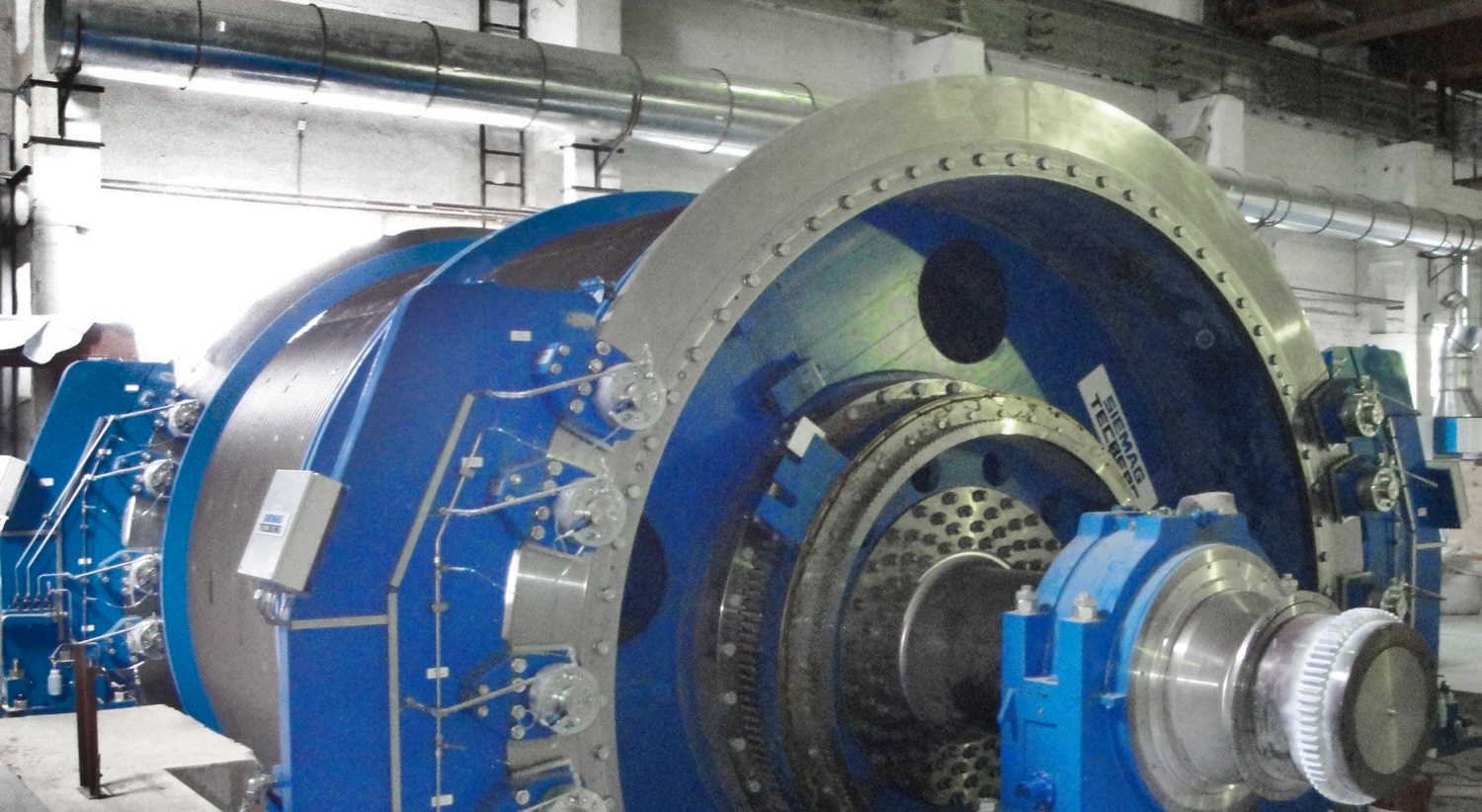

Double drum

Winder, that arranges two drums on the machine shaft.

Winder, that arranges two drums on the machine shaft, where at least one drum is designed as a floating drum, mounted onto the shaft using bushes. This particular drum will only turn with the shaft if the associated clutch is engaged.

If this clutch is disengaged, the other drum can run at a low speed (normally up to 2 m/s). In this way, the position of the two drums and the attached conveyances can be changed relatively to each other.

This is done for rope shortening purposes o for serving another floor through two hoistway.

TECHNICAL FEATURES

- Arrangement of two drums on a common shaft

- One drum designed as a floating drum

- Conveyances run in two hoistways with clutch engaged

- Movement of one conveyance independently of the other in a shaft with clutch disengaged

TECHNICAL DATA

- Drum diameter: 1,8 to 6,3 m

- Payload: 4 to 35 t

- Operating load: 19 to 196 t

- Drive output: 187 to 4,800 kW

- Shaft depth: up to 2,500 m