Haiger, June 2020.

LIFTING EQUIPMENT FOR SMOOTH SHIPPING TRAFFIC BETWEEN BERLIN (GERMANY) AND STETTIN (POLAND)

Since 2009, the new Niederfinow ship lift has been under construction as part of the German federal government‘s „anti-congestion program“. Once it is opened, it will replace the oldest ship lift in Germany, which is still in operation from the 1930s. Since 1934, this protected industrial monument has enabled watercraft to surmount a 36-metre height differential on the 250-year-old waterway. The new ship lift at the eastern end of the Havel-Oder federal waterway will be additionally supported by the old lift for a certain period after opening.

The new Niederfinow ship lift is of great importance for transport infrastructure networking in Europe. The new construction will eliminate a major bottleneck on the only trans-European east-west waterway link between Szczecin and Duisburg. The new construction will enable modern freight and container ships, which are becoming ever wider and longer, to also utilise this waterway with up to 104 standard cargo containers.

This fulfils the valid European standard and also creates the prerequisite to increasingly shift freight transport to the environmentally compatible and cost-effective mode of water transport. The end of the construction and commissioning work as well as the opening are planned for the beginning of 2021.

Due to the positive experience with the virtually trouble-free operation of the old ship lift for decades, the basic mechanical principle was retained for the new ship lift so that the approximately 20,000 watercraft per year can continue to surmount the incline in the terrain without any problems.

Just as with the old ship lift with its up to 150,000 visitors per year, the new lift will be on display. The interior can be explored via lifts and bridges, and the process of raising and lowering the watercraft can be observed in the visitor galleries at a height of almost 50 metres.

SIEMAG TECBERG is responsible for the sophisticated machine technology

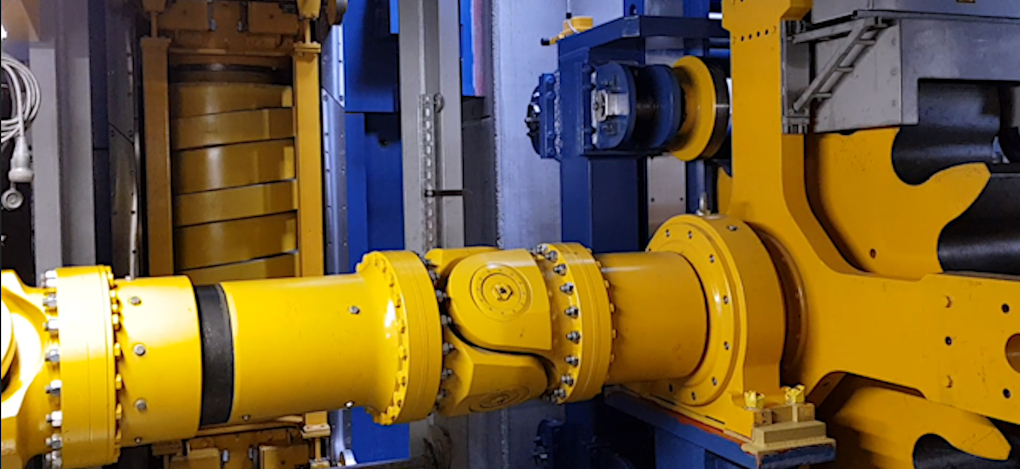

As a partner to Niederfinow Consortium, the SIEMAG TECBERG group with its knowledge-based services in the fields of engineering / implementation planning, procurement, production supervision, assembly supervision and support during commissioning is responsible for the sophisticated machine technology. This includes for example the trough drive, trough safety device, trough holding device, trough guides and counterweight system. In future, vessels up to 11.45 metres wide and 110 metres long will be able to pass through the 115 metre long Niederfinow trough.

This is enabled by the ship lift‘s lifting technology, which functions according to the Archimedean counterweight principle like a Koepe hoisting machine, as the mass of the waterfilled trough remains the same when a ship enters.

The SIEMAG TECBERG group is contributing its decades of experience with counterweight systems in shaft hoisting to this project. In the new elevator, the filled trough hangs on 224 60-mm diameter steel cables, which are connected to the counterweight groups on both sides via 112 double cable pulleys with a diameter of 4 metres.

The counterweight principle minimises the drive‘s installed output for lifting and lowering the approximately 9,800-tonne ship‘s trough. A total of 1,280 kW of drive output is installed in four drive units.

This results in a travel time for the 36-metre lifting height of approximately three minutes compared to around five minutes for the old lift. For potential accident scenarios, a trough safety system analogous to the old lift is installed, which consists of four turning bolts with internally-threaded columns attached at the pylons and which will hold the ship trough securely in case of excessive imbalance.

Based on the client‘s concept, the SIEMAG TECBERG group further completed the hydraulically operated trough holding devices in the upper and lower berthing positions as well as the horizontal trough guiding devices in the longitudinal and transverse direction of the structure.

During commissioning in April of this year, a first trough lift was carried out as an empty lift - without ship, but with water-filled trough - to the upper berthing position in order to successfully test the trough drive for functionality.